Protection during rainfall

Dealing with the changing weather conditions during construction is a tedious task. Protecting the structure from rain takes time and increases building costs. The lack of proper weather protection and exposure of the building to weather conditions often causes building work delays.

Fortunately, you can do better. Apply construction material to the sheathing of the walls and roof, thanks to which you will not only strengthen the frame of the building, but also protect it from precipitation. To avoid downtime and additional costs, get to know our new product – Paged DryGuard.

Plywood with hydrophobic coating

A high performance softwood plywood produced from FSC certified wood with special surface treatment that allows its users to save time during construction. Its water-repellent surface reduces water absorption and does not impede air permeability. The surface agent applied during manufacturing post processing slows down the rate of moisture penetration and helps maintain the rigidity and dimensional stability of the panel throughout its life-cycle.

The evaluation of the new product was carried out by Paged LabTech. All tests were based on the PN-EN 927-5 standard, which assesses the liquid water permeability. The results are shown in the chart below.

Paged Dry Guard in natural weather conditions

Our new product has also been exposed to natural weather conditions on the basis of the PN-EN 927-3 standard. The panels impregnated with the hydrophobic solution were field tested for a period of 6 months at our field station in the north-eastern region of Poland. The panels were inclined at an angle of 45°relative to the level at which the samples were positioned. The frontal surface was directed towards the equator. During the assessment general appearance, mold development, color change, cracking, gloss were evaluated.

The results of the research showed that the coating used in Paged DryGuard protects not only against rain, but also against the development of mold. After 6 months, mold growth was below 10% of the tested area. Only minor cracks appeared on the coating up to a maximum of a few; overall appearance was rated as very good. This is important because when building a house we want to take care of the quality of indoor air for years. Such protection is an additional advantage of Paged DryGuard plywood.

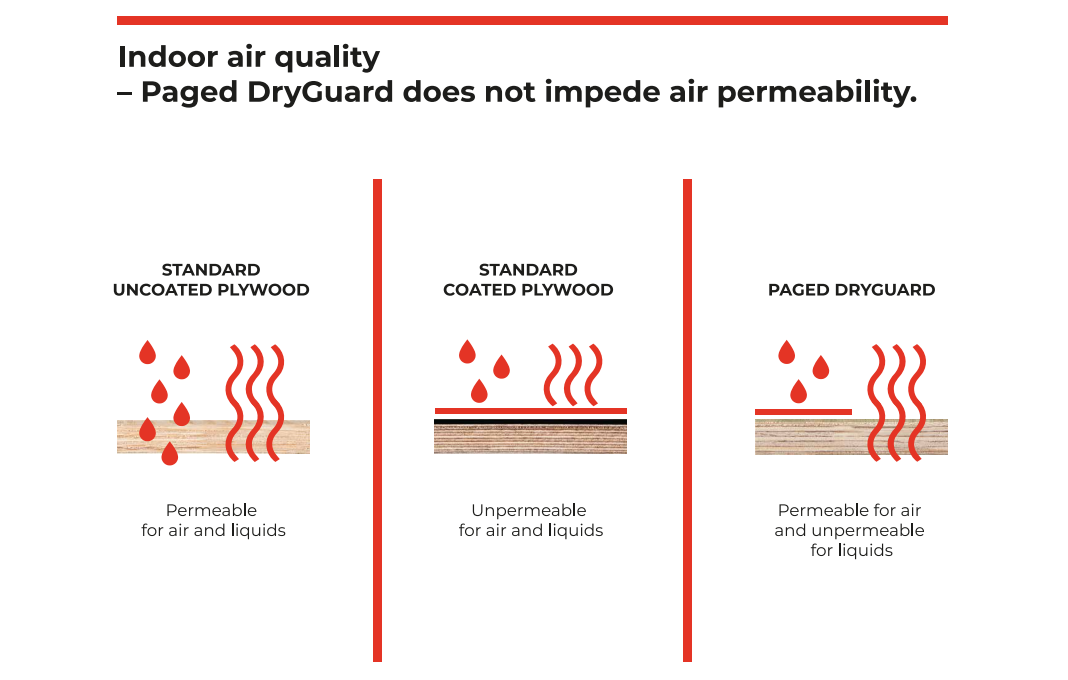

Air permeability

Importantly, the hydrophobic surface inhibits water absorption, but does not adversely affect the diffusion of water vapor (gas penetration). Wood can therefore breathe during construction and use, as well as dry freely after the occurrence of precipitation.

The prepared samples were dried for 72 hours at 80 ° C. In an airtight glass container (hop-outer) a saturated solution of diammonium phosphate was prepared. After drying, the samples were weighed and placed in a desiccator over the solution (without contact). The container is tightly closed. The humidity in the container reached 95% (the so-called moist air). The samples were then weighed after 1, 2, 4, 24, 48, 72, 96, 120 and 168 hours. After each measurement, the samples were deposited in a de-desiccator immediately. Non-impregnated thick-layer pine wood was used as reference samples. The study showed that Paged DryGuard does not limit the diffusion of water vapor.

Applications of Paged DryGuard

This plywood will be used primarily in construction – the construction of roofs, ceilings and partition walls. It will also work well in the renovation of buildings due to the lightness and ease of processing. It can be used for the production of floors, packaging, motorhomes, mobile homes and fences.